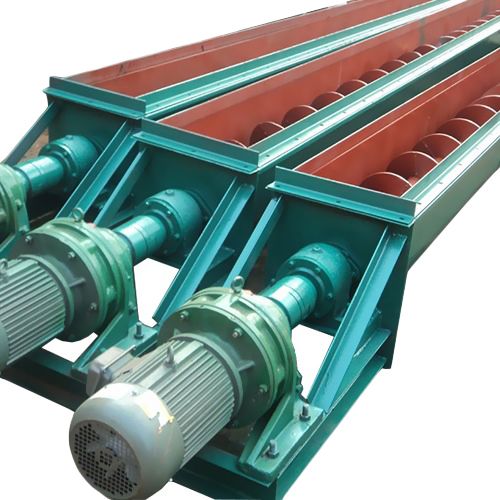

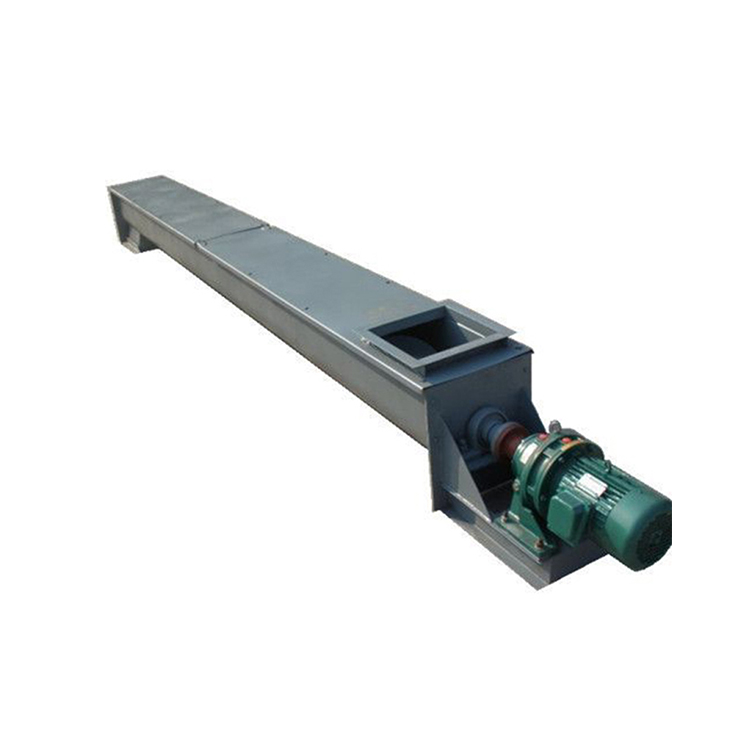

Screw conveyor runtuyan

Prinsip gawé:

Nalika aci screw rotates, bahan ngan bisa maju sapanjang handap trough of conveyor handapeun push of sabeulah alatan gravitasi bahan jeung gaya gesekan antara bahan jeung témbok trough, nu kawas tarjamahan. gerakan nut nu teu bisa diputer sapanjang screw puteran [3].Gerakan bahan dina bearing tengah gumantung kana dorong tina bahan pindah ka hareup tukangeun.Ku alatan éta, angkutan bahan dina conveyor nu, mangrupakeun jenis gerakan ngageser.Dina raraga nyieun aci screw dina kaayaan tensile leuwih nguntungkeun, alat nyetir na unloading port umumna disimpen dina tungtung sarua conveyor nu, sarta port feed disimpen deukeut buntut tina tungtung séjén sajauh mungkin.Sabeulah spiral puteran bakal diangkut ku bahan, ku kituna bahan teu muterkeun kalawan gaya agul conveyor screw nyaeta beurat bahan sorangan jeung résistansi gesekan tina screw conveyor casing kana bahan.Jenis permukaan sabeulah nurutkeun bahan conveying boga tipe permukaan padet, tipe permukaan sabuk, tipe permukaan sabeulah jeung saterusna.Aci screw tina conveyor screw dina arah gerakan bahan terminal dorong bearing kalayan bahan pikeun gaya réaksi axial of screw nu, dina kaptén leuwih panjang, kudu ditambahkeun di tengah bearing nongkrong.

Screw conveyor runtuyan screw conveyor dibagi kana screw conveyor horizontal sarta screw conveyor nangtung ti sudut arah kapindahan bahan conveying.Ieu utamana dipaké pikeun conveying horizontal sarta ngangkat nangtung tina rupa-rupa bahan leupas, kayaning bubuk, granular sarta potongan leutik.Teu cocog pikeun conveying deteriorative, kentel, caking atawa suhu luhur, tekanan-tahan jeung rélatif luhur.bahan husus kalawan corrosiveness tinggi.Screw conveyor loba dipaké dina sagala rupa industri, kayaning bahan wangunan, industri kimia, kakuatan, metallurgy, tambang batubara, gandum jeung industri lianna.Contona, tambang batubara, lebu, slag, semén, gandum, jeung sajabana, suhu bahan kirang ti 200 C.

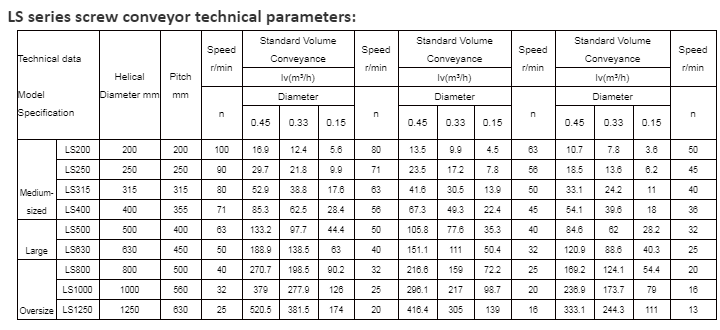

LS runtuyan screw conveyor parameter teknis:

| Modél data téknis Spésifikasi | Hélik diaméterna mm | Pitch | Laju r / mnt | Baku Volume Conveyance | Laju r / mnt | Baku Volume Conveyance | Laju r / mnt | Baku Volume Conveyance | Laju r / mnt | Baku Volume Conveyance | |||||||||

| lv (m³ / h) | lv (m³ / h) | lv (m³ / h) | lv (m³ / h) | ||||||||||||||||

| n | Diameter | n | Diameter | n | Diameter | n | Diameter | ||||||||||||

| 0.45 | 0.33 | 0.15 | 0.45 | 0.33 | 0.15 | 0.45 | 0.33 | 0.15 | 0.45 | 0.33 | 0.15 | ||||||||

| Sedeng | LS200 | 200 | 200 | 100 | 16.9 | 12.4 | 5.6 | 80 | 13.5 | 9.9 | 4.5 | 63 | 10.7 | 7.8 | 3.6 | 50 | 8.5 | 6.2 | 2.8 |

| LS250 | 250 | 250 | 90 | 29.7 | 21.8 | 9.9 | 71 | 23.5 | 17.2 | 7.8 | 56 | 18.5 | 13.6 | 6.2 | 45 | 14.9 | 10.9 | 5 | |

| LS315 | 315 | 315 | 80 | 52.9 | 38.8 | 17.6 | 63 | 41.6 | 30.5 | 13.9 | 50 | 33.1 | 24.2 | 11 | 40 | 26.4 | 19.4 | 8.8 | |

| LS400 | 400 | 355 | 71 | 85.3 | 62.5 | 28.4 | 56 | 67.3 | 49.3 | 22.4 | 45 | 54.1 | 39.6 | 18 | 36 | 43.2 | 31.7 | 14.4 | |

| Gede | LS500 | 500 | 400 | 63 | 133.2 | 97.7 | 44.4 | 50 | 105.8 | 77.6 | 35.3 | 40 | 84.6 | 62 | 28.2 | 32 | 67.7 | 49.6 | 22.6 |

| LS630 | 630 | 450 | 50 | 188.9 | 138.5 | 63 | 40 | 151.1 | 111 | 50.4 | 32 | 120.9 | 88.6 | 40.3 | 25 | 94.4 | 69.3 | 31.5 | |

| Geuning | LS800 | 800 | 500 | 40 | 270.7 | 198.5 | 90.2 | 32 | 216.6 | 159 | 72.2 | 25 | 169.2 | 124.1 | 54.4 | 20 | 135.4 | 99.3 | 45.1 |

| LS1000 | 1000 | 560 | 32 | 379 | 277.9 | 126 | 25 | 296.1 | 217 | 98.7 | 20 | 236.9 | 173.7 | 79 | 16 | 189.5 | 139 | 63.2 | |

| LS1250 | 1250 | 630 | 25 | 520.5 | 381.5 | 174 | 20 | 416.4 | 305 | 139 | 16 | 333.1 | 244.3 | 111 | 13 | 270.7 | 198.5 | 90.2 | |

*Debu Feeder Klep Screw Conveyor Pikeun Debu kolektor

Panjelasan Produk

U ngawangun screw conveyor mangrupakeun U ngawangun screw conveyor of screw conveyors.Ieu adopts DIN15261-1986 baku sarta dirancang jeung dijieun pikeun minuhan standar profésional ti JB / T7679-2008 "Screw Conveyor".U ngawangun screw conveyor disebut oge screw feeder, U ngawangun screw conveyor, trough screw conveyor, screw conveyor, auger, jsb Ieu adopts DIN15261-1986 baku sarta dirancang jeung dijieun luyu jeung JB / T7679-2008 "Screw conveyor. "Standar profésional

Keunggulan produk U screw conveyor:

1. Instalasi jeung disassembly teu kedah gerakan axial, mandrel panjang, kirang nongkrong, sarta titik gagalna pangsaeutikna

2. Ngadopsi struktur diaméter variabel pikeun ngaronjatkeun volume bearing nongkrong

3. Dina rentang, éta bisa kalawan bébas muterkeun kalawan résistansi conveying ulah jams bahan atawa blockages

4. Sirah jeung buntut bearing korsi téh sadayana di luar cangkang, kalayan hirup layanan panjang

5. kinerja sealing Alus, operasi stabil sarta dipercaya, multi-titik loading na unloading sarta operasi di tengah.